The E-commerce Legal Mistakes That Shut Down Online Stores

The e-commerce boom has created incredible opportunities for entrepreneurs to build thriving online businesses. However, beneath the surface of every...

12 min read

LegalGPS : Dec. 2, 2025

Choosing the wrong dropshipping supplier can destroy your business faster than almost any other mistake. While dropshipping offers entrepreneurs an attractive path to e-commerce success without inventory investment, the supplier relationship forms the foundation of everything your customers experience.

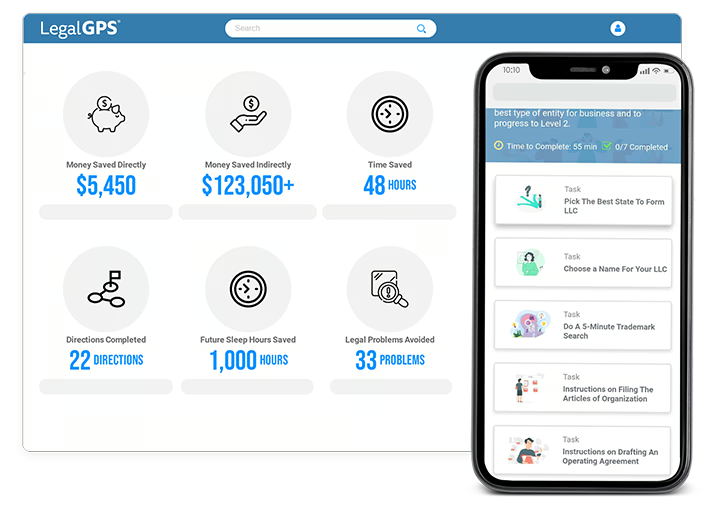

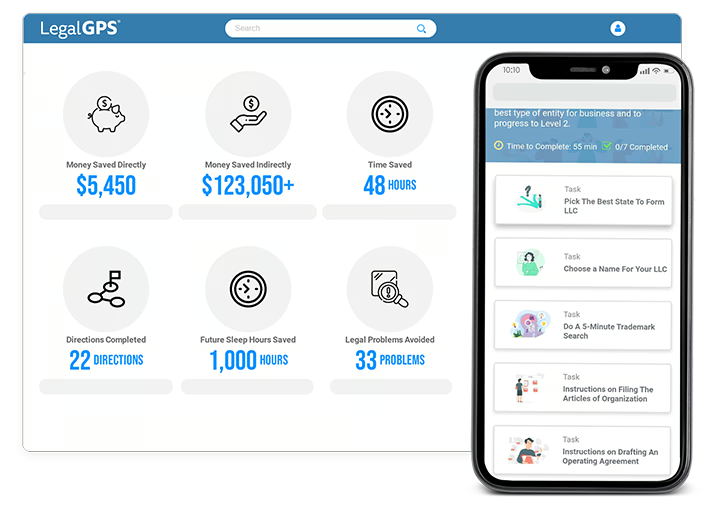

Legal GPS Pro

Protect your business with our complete legal subscription service, designed by top startup attorneys.

The wrong supplier choice doesn't just cost you money—it can trigger customer service disasters, legal liability, damaged reputation, and complete business failure. Understanding how to evaluate and select reliable suppliers becomes critical for long-term success in the dropshipping business model.

Your dropshipping supplier essentially becomes your business partner in everything that matters to customers. They handle product quality, shipping speed, packaging presentation, and often customer service communication. When suppliers fail, customers blame your business, not the supplier they never knew existed.

Poor supplier choices create cascading problems throughout your entire operation. Late shipments generate angry customers and refund requests. Quality issues trigger returns, negative reviews, and potential legal liability. Communication problems with suppliers leave you unable to provide customers with accurate information about their orders.

The financial impact extends beyond immediate losses from returns and refunds. Bad suppliers damage your brand reputation through negative reviews, social media complaints, and word-of-mouth warnings. Recovering from supplier-induced reputation damage often costs more than the original business investment.

Consider the typical progression of supplier-related business failure. Initial problems seem manageable—a few late shipments or quality complaints. As issues multiply, customer service costs increase dramatically. Negative reviews accumulate, reducing conversion rates and increasing customer acquisition costs. Eventually, the business becomes unsustainable as operating costs exceed revenue potential.

Drop Shipping Agreement defining supplier-seller terms, fulfillment, and liability limits.

Trusted by 1,000+ businesses to safeguard their LLCs.

Beyond obvious costs like refunds and returns, poor suppliers create expensive operational burdens that many entrepreneurs overlook. Customer service costs escalate when suppliers create problems requiring extensive communication and problem-solving. Time spent managing supplier issues prevents focus on business growth activities like marketing and product development.

Marcus Chen launched TechGadgets Plus selling smartphone accessories through what appeared to be a reputable Chinese supplier. The supplier offered competitive pricing and claimed 3-5 day shipping times. After three months of operation, Marcus calculated his total losses from supplier problems.

The supplier consistently shipped defective products, generating a 35% return rate compared to the industry average of 8%. Processing returns cost Marcus approximately $12 per incident in customer service time, shipping costs, and administrative overhead. With 800 orders during the period, defective products cost him $9,800 in return processing alone.

Late shipments became routine, with actual delivery times averaging 12-18 days instead of the promised 3-5 days. Customer complaints required extensive phone and email support, costing Marcus an estimated $15,000 in time and customer service staff wages. Emergency expedited shipping to satisfy angry customers added another $8,200 in unexpected costs.

Most damaging, negative reviews from dissatisfied customers reduced Marcus's conversion rate from 4.2% to 1.8%. The reduced conversion rate meant his advertising costs increased dramatically to maintain the same sales volume. His total advertising cost per acquisition nearly doubled, adding approximately $12,000 in additional marketing expenses during the three-month period.

Create a comprehensive tracking system for all supplier-related costs, not just obvious expenses like refunds. Track customer service hours spent on supplier issues, additional shipping costs for expedited replacements, advertising cost increases due to reduced conversion rates, and opportunity costs from time spent managing problems instead of growing your business. Most entrepreneurs underestimate total supplier costs by 60-80% when they only count direct expenses.

Sarah Martinez built FashionForward selling women's clothing through multiple suppliers across different countries. Her biggest mistake was failing to establish clear communication protocols with suppliers before problems arose. When customer complaints started increasing, suppliers became unresponsive or provided contradictory information.

One particularly problematic situation involved 200 dresses that arrived in completely wrong sizes. The supplier initially claimed the sizing was correct, then blamed the manufacturer, then offered a 30% refund but refused to accept returns. Sarah spent six weeks communicating with suppliers while angry customers demanded immediate solutions.

The communication breakdown forced Sarah to process $8,400 in full refunds using her own money while fighting to recover costs from suppliers. More importantly, the extended resolution time damaged customer relationships beyond repair. Twelve customers who received full refunds still left negative reviews citing poor communication and slow problem resolution.

Sarah's experience highlights how supplier communication problems create expensive customer service situations that entrepreneurs must solve independently while fighting to recover costs from uncooperative suppliers.

David Rodriguez learned about legal liability the hard way when his home decor supplier shipped electrical items that didn't meet U.S. safety standards. Three customers reported minor electrical issues, including one who claimed the problem caused damage to their home's electrical system.

The supplier had provided documentation claiming UL certification, but the paperwork proved fraudulent when investigated by David's insurance company. David faced potential liability for property damage and was forced to issue immediate recalls for all electrical items sold during a four-month period.

Legal consultation costs exceeded $8,000, and David's insurance company required additional coverage with significantly higher premiums. The recall process cost approximately $15,000 in product refunds and return shipping. Most seriously, the legal scare forced David to completely restructure his supplier verification process and avoid entire product categories he had planned to expand into.

Successful supplier evaluation requires systematic assessment across multiple criteria that directly impact customer experience and business operations. Rather than focusing solely on pricing and product availability, comprehensive evaluation examines the supplier's ability to consistently deliver quality products on time while maintaining professional communication standards.

Verify supplier business registration and licensing through appropriate government databases. Request financial references or bank verification letters that demonstrate the supplier's ability to maintain consistent operations. Financial instability in suppliers often manifests as sudden quality reductions, shipping delays, or communication problems when cash flow becomes tight.

Examine the supplier's business longevity and growth trajectory. Suppliers operating for less than two years carry higher risk of sudden closure or dramatic operational changes. Request information about their customer base diversity—suppliers overly dependent on one or two major clients face higher closure risk if those relationships end.

Investigate the supplier's physical facilities and operational capacity through virtual tours, third-party verification services, or in-person visits when possible. Suppliers operating from residential addresses or unwilling to provide facility information often lack the infrastructure necessary for consistent performance.

Establish clear quality standards and testing procedures before entering any supplier relationship. Request detailed product specifications, manufacturing processes, and quality control procedures. Suppliers unable or unwilling to provide comprehensive quality documentation often lack systematic approaches to consistency.

Order multiple product samples across different time periods to evaluate consistency. Quality variations between samples indicate unreliable manufacturing processes that will create customer satisfaction problems. Test products under normal use conditions and compare results against product claims and specifications.

Examine packaging quality and presentation standards. Poor packaging often reflects overall supplier attention to detail and professionalism. Products arriving damaged due to inadequate packaging create customer service problems and return costs that reduce profitability.

Request detailed shipping performance data including average processing times, carrier relationships, and delivery confirmation procedures. Suppliers claiming extremely fast shipping times without providing supporting logistics information often make unrealistic promises they cannot consistently deliver.

Test shipping performance through multiple sample orders placed at different times and seasons. Shipping performance often varies significantly during peak seasons, holidays, or high-demand periods. Establish realistic shipping time expectations based on actual testing rather than supplier claims.

Verify the supplier's ability to provide tracking information and shipment updates throughout the delivery process. Customers expect transparent communication about order status, and suppliers unable to provide detailed tracking create customer service burdens for your business.

Evaluate supplier responsiveness and communication quality through detailed interactions before committing to business relationships. Response times, English proficiency levels, and willingness to address concerns provide strong indicators of future customer service experiences.

Test supplier knowledge about their products, policies, and procedures through specific questions about scenarios you're likely to encounter. Suppliers unable to provide clear, accurate information about their own products and services will create ongoing communication challenges.

Establish clear communication protocols including response time expectations, escalation procedures for urgent issues, and regular update schedules for ongoing orders. Suppliers unwilling to commit to specific communication standards often lack the customer service infrastructure necessary for successful dropshipping partnerships.

Recognizing supplier warning signs early prevents costly business relationships and protects your brand reputation. Many red flags become apparent during initial supplier research and communication, while others emerge through testing and sample orders.

Create a standardized red flag tracking system that documents concerns, supplier responses, and resolution attempts. This documentation becomes valuable for making objective supplier decisions and avoiding emotional attachment to suppliers who consistently demonstrate problems. Share your red flag criteria with team members to ensure consistent supplier evaluation across your organization.

Tom Williams discovered multiple red flags while evaluating a garden tool supplier, but ignored them due to attractive pricing and product selection. The supplier's website contained numerous grammatical errors and lacked detailed contact information. Customer service responses came from personal email addresses rather than business accounts.

Product samples arrived with different branding than advertised, and the supplier provided conflicting explanations when questioned. The supplier requested payment through unconventional methods and offered significant discounts for immediate large orders. Tom ignored these warning signs and placed a substantial initial order.

The supplier disappeared completely after receiving payment, and Tom lost $12,000 with no recourse. Investigation revealed the supplier had operated under multiple business names and had defrauded numerous other entrepreneurs using identical tactics. Tom's experience demonstrates how multiple red flags typically appear together and should never be ignored regardless of apparent benefits.

Dramatically lower pricing compared to market rates often indicates quality compromises, unsustainable business models, or fraudulent operations. Suppliers offering prices significantly below competitors either lack understanding of their true costs or use pricing as bait for fraudulent schemes.

Investigate unusual pricing through detailed cost breakdowns and comparison with similar suppliers. Legitimate suppliers can explain their cost advantages through specific operational efficiencies, volume discounts, or manufacturing innovations. Vague explanations for low pricing typically indicate problems you'll discover after committing to the relationship.

Be particularly cautious of suppliers offering temporary promotional pricing that seems too attractive. These pricing strategies often attract new customers who become locked into relationships before discovering hidden costs, quality problems, or service limitations.

Suppliers who respond slowly or inconsistently to initial inquiries will typically provide worse communication during ongoing business relationships. Initial supplier communication represents their best effort to impress potential customers—communication quality generally declines after establishing business relationships.

Language barriers that prevent clear communication about products, policies, and procedures create ongoing customer service challenges. While working with international suppliers often requires patience with language differences, inability to communicate clearly about basic business topics indicates future problems.

Suppliers who provide evasive answers, change their explanations frequently, or fail to address specific questions directly often lack the knowledge or infrastructure necessary for professional business relationships.

Professional suppliers maintain comprehensive documentation for all aspects of their operations including business licenses, insurance certificates, product specifications, quality certifications, and shipping procedures. Suppliers unable or unwilling to provide appropriate documentation typically lack professional business practices.

Request specific documentation during supplier evaluation and be suspicious of suppliers who claim documents are unavailable, in processing, or provided only after establishing business relationships. Legitimate suppliers understand documentation requirements and maintain readily available paperwork.

Verify documentation authenticity through appropriate channels rather than accepting supplier-provided certificates at face value. Fraudulent suppliers often provide convincing fake documentation that appears legitimate without independent verification.

Thorough supplier due diligence prevents costly mistakes and provides confidence in business relationships. Comprehensive evaluation takes time and effort but saves significantly more resources than dealing with supplier problems after they arise.

Verify supplier business registration through appropriate government databases and business verification services. Confirm the business operates legally and maintains required licenses for their industry and location. Unregistered or improperly licensed suppliers create legal liability risks for your business.

Research the supplier's reputation through industry associations, trade publications, and online business directories. Contact relevant industry organizations to verify membership claims and check for any disciplinary actions or complaints.

Investigate the supplier's online presence including website quality, social media activity, and customer interactions. Professional suppliers maintain consistent branding and regular communication across all channels. Poor online presentation often indicates lack of attention to business details that will affect your customer experience.

Place multiple sample orders across different time periods to evaluate consistency in product quality, shipping times, and communication. Single sample orders provide insufficient data for predicting long-term supplier performance. Test during different seasons and order volumes when possible.

Document all aspects of the sample order experience including response times, product accuracy, packaging quality, shipping speed, and communication clarity. Create standardized evaluation criteria that enable objective comparison between different suppliers.

Test products under realistic use conditions and compare performance against product specifications and marketing claims. Products that fail to meet specifications during testing will create customer satisfaction problems and potential legal liability.

Request references from current customers and contact them directly to discuss their experiences with the supplier. Focus on long-term customers who can provide insights into how the supplier handles problems and maintains relationships over time.

Research supplier reviews and ratings across multiple platforms including trade websites, social media, and business directories. Look for patterns in complaints and pay attention to how suppliers respond to negative feedback.

Investigate any legal disputes, bankruptcy filings, or regulatory actions involving the supplier through public records searches. Suppliers with histories of legal problems often repeat similar issues with new customers.

Develop a standardized scoring system that objectively evaluates all potential suppliers using identical criteria. Include categories for business legitimacy, communication quality, product quality, shipping performance, and customer service. Assign specific point values to each category and establish minimum scores for supplier acceptance. This systematic approach prevents emotional decision-making and ensures consistent evaluation standards across your team.

Comprehensive supplier agreements establish clear expectations, protect against common problems, and provide legal recourse when issues arise. Many dropshipping entrepreneurs operate without formal agreements, creating unnecessary risks and limiting their options when suppliers fail to perform.

Jennifer Park learned the value of detailed supplier agreements when her sporting goods supplier began consistently shipping damaged products. The damages appeared to result from poor packaging and rough handling during shipping, affecting approximately 25% of orders during a two-month period.

Jennifer's supplier agreement included specific packaging requirements, damage rate thresholds, and automatic remedies for performance failures. When damage rates exceeded the agreed 5% threshold, the contract automatically triggered penalty payments and required the supplier to implement corrective measures within 30 days.

The supplier initially resisted paying penalties and claimed the damage was due to carrier handling rather than packaging problems. However, the detailed contract terms provided clear evidence of supplier responsibility and specific remedies. The supplier ultimately paid $8,500 in penalties and invested in improved packaging that reduced damage rates to acceptable levels.

Without the detailed agreement, Jennifer would have faced expensive negotiations, potential legal disputes, and continued product damage problems while fighting for supplier cooperation. The contract provided immediate remedies and clear consequences that motivated rapid supplier response.

Quality standards and specifications must be clearly defined in measurable terms rather than subjective descriptions. Include specific requirements for product materials, manufacturing processes, packaging standards, and acceptable defect rates. Vague quality language creates disputes and makes enforcement difficult.

Shipping and delivery requirements should specify exact timelines, shipping methods, tracking procedures, and carrier relationships. Include penalties for late shipments and define emergency shipping procedures for time-sensitive orders. Establish clear procedures for communicating shipping delays and alternative arrangements.

Pricing and payment terms must address price changes, minimum order requirements, payment schedules, and currency fluctuations for international suppliers. Include provisions for promotional pricing, volume discounts, and annual pricing negotiations to prevent unexpected cost increases.

Establish comprehensive quality control procedures including inspection requirements, sample testing protocols, and corrective action procedures for quality failures. Define specific metrics for acceptable quality levels and automatic remedies when standards are not met.

Return and refund policies must clearly allocate responsibility between your business and the supplier for different types of returns. Include procedures for product defects, shipping damage, customer satisfaction issues, and product recalls.

Define inventory management responsibilities including stock level monitoring, product discontinuation notices, and seasonal availability planning. Poor inventory communication creates customer service problems and lost sales opportunities.

Termination procedures should address both immediate termination for serious violations and standard termination with appropriate notice periods. Include specific violations that trigger immediate termination such as fraud, safety violations, or consistent performance failures.

Dispute resolution procedures help avoid expensive litigation while providing mechanisms for addressing disagreements. Include mediation requirements before legal action and specify jurisdiction for legal disputes. International suppliers often prefer arbitration over court proceedings.

Include comprehensive confidentiality and non-compete provisions that protect your business information and customer relationships. Suppliers should not be permitted to directly contact your customers or use your business information for competing purposes.

Knowing when to end supplier relationships protects your business from escalating problems and maintains customer satisfaction. Many entrepreneurs delay supplier changes too long, hoping problems will improve rather than protecting their business interests.

Establish specific performance thresholds that automatically trigger supplier evaluation and potential termination. Quality metrics such as defect rates exceeding 10%, return rates above industry averages, or customer complaints about specific suppliers provide objective criteria for supplier changes.

Shipping performance standards including on-time delivery rates below 85%, average shipping times exceeding promises by more than 25%, or consistent tracking and communication problems indicate suppliers that cannot meet customer expectations.

Communication and customer service failures such as response times exceeding 48 hours, language barriers preventing clear communication, or unwillingness to address customer concerns require immediate attention and potential supplier replacement.

Plan supplier transitions carefully to minimize customer impact and business disruption. Identify replacement suppliers and complete full evaluation procedures before terminating current suppliers. Overlap periods allow testing new suppliers while maintaining service levels.

Communicate proactively with customers about potential shipping delays or product changes during supplier transitions. Transparency about improvements often generates customer appreciation rather than complaints when properly managed.

Update all marketing materials, product listings, and customer communications to reflect any changes in specifications, shipping times, or policies resulting from new supplier relationships.

Customer communication during supplier transitions should focus on service improvements and enhanced quality rather than supplier problems. Position changes as proactive business improvements that benefit customers rather than reactive responses to problems.

Offer special promotions or incentives to customers who experience inconvenience during transition periods. Small gestures of appreciation often prevent negative reviews and maintain customer loyalty during temporary service disruptions.

Monitor customer feedback closely during transition periods and respond quickly to any concerns or complaints. Fast response to transition-related issues demonstrates your commitment to customer satisfaction regardless of supplier challenges.

Smart supplier selection forms the foundation of sustainable dropshipping success. Take time to thoroughly evaluate potential suppliers, document all interactions, and establish clear agreements before committing to business relationships.

Legal GPS offers comprehensive contract templates specifically designed for dropshipping businesses, including supplier agreements that protect your interests while establishing clear performance expectations. Our Pro subscription provides access to educational resources that help you avoid common legal pitfalls that destroy dropshipping businesses.

Don't let poor supplier choices destroy your entrepreneurial dreams. Protect your business with proper legal documentation and systematic supplier evaluation procedures that ensure long-term success in competitive e-commerce markets.

Legal GPS Pro

Protect your business with our complete legal subscription service, designed by top startup attorneys.

|

Premium Template

Single-use Template |

Legal GPS Pro

Unlimited Access, Best Value |

|

|

| Choose Template | Learn More |

| Trusted by 1000+ businesses | |

Table of Contents

The e-commerce boom has created incredible opportunities for entrepreneurs to build thriving online businesses. However, beneath the surface of every...

Software has become the backbone of modern business operations. From customer relationship management to accounting systems, companies rely heavily...

The online course industry generates over $325 billion annually, yet countless creators watch their profits vanish due to preventable legal mistakes....