Mobile App Development Gone Wrong: How to Protect Your Investment

Launching a mobile app feels like printing money until legal disasters strike. Most entrepreneurs dive into development thinking their biggest risk...

10 min read

LegalGPS : Dec. 6, 2025

The 3D printing industry has exploded into a $15.8 billion market, revolutionizing how businesses create prototypes, manufacture parts, and bring products to market. However, this technological advancement has also created a minefield of intellectual property risks that can devastate unprepared companies.

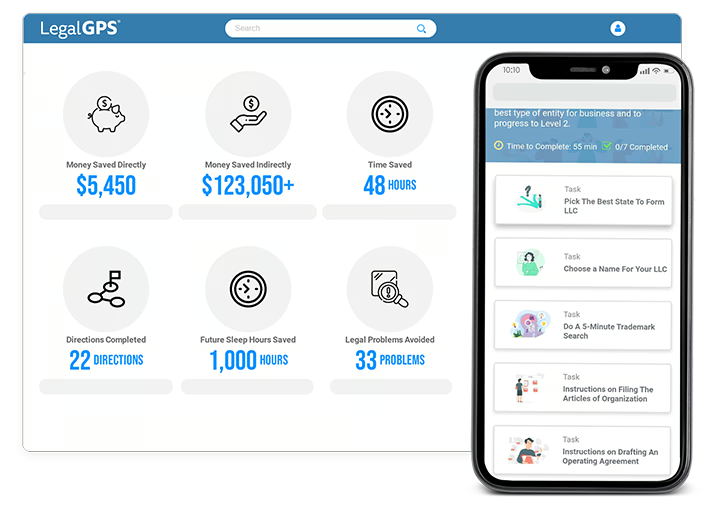

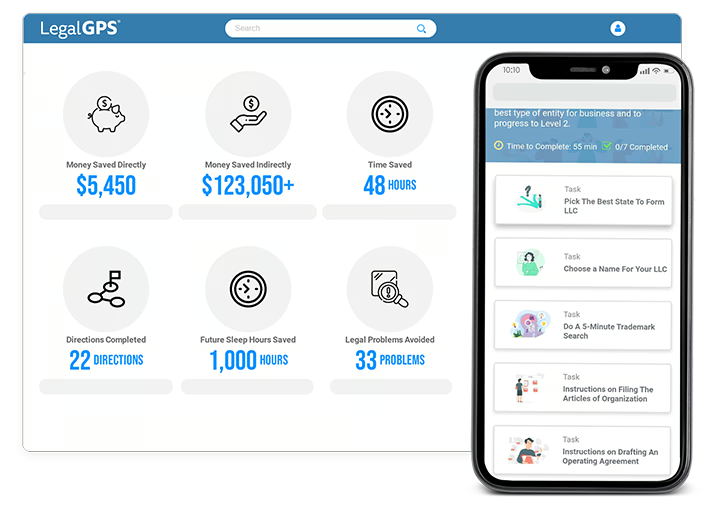

Legal GPS Pro

Protect your business with our complete legal subscription service, designed by top startup attorneys.

Every day, businesses using 3D printing technology face potential lawsuits, cease-and-desist orders, and financial penalties that can reach millions of dollars. The ease of copying existing designs, combined with the complex web of patents, copyrights, and trademarks protecting various innovations, makes IP compliance more critical than ever for 3D printing operations.

3D printing democratizes manufacturing, but it also democratizes IP infringement. Traditional manufacturing required significant investment in tooling and setup costs, which naturally limited unauthorized reproduction of protected designs. With 3D printing, anyone with a printer and digital file can potentially infringe on someone else's intellectual property rights.

The digital nature of 3D printing creates unique vulnerabilities. Design files can be easily shared, modified, and distributed across global networks. What might seem like innocent customization or improvement of an existing design could actually constitute patent infringement or copyright violation.

IP violations in 3D printing carry severe financial consequences that extend far beyond simple fines. Companies face potential damages calculations based on lost profits, reasonable royalties, and in cases of willful infringement, triple damages under patent law.

The legal costs alone can cripple small to medium-sized businesses. Patent litigation typically costs between $1-5 million per case, even when companies successfully defend themselves. Copyright and trademark disputes, while generally less expensive, still routinely cost hundreds of thousands of dollars in legal fees.

3D Printing Services Agreement covering scope, materials, deadlines, and IP terms.

Trusted by 1,000+ businesses to safeguard their LLCs.

Patent law protects the functional aspects of inventions, covering everything from the shape of a mechanical component to the method used to manufacture it. In 3D printing, patent infringement can occur through direct copying of protected designs or through the use of patented manufacturing processes.

The challenge lies in identifying which aspects of a design might be patent-protected. Unlike copyrights and trademarks, which are often more obvious, patents can protect non-visible features, internal mechanisms, or specific dimensional relationships that aren't immediately apparent from examining the finished product.

Many businesses mistakenly believe that making "small changes" to an existing design eliminates patent infringement risk. However, patent protection typically covers the overall inventive concept, and minor modifications rarely provide adequate protection against infringement claims.

MakerBot Industries learned this lesson the hard way when Stratasys filed a patent infringement lawsuit over their desktop 3D printing technology. The dispute centered on fundamental 3D printing processes that MakerBot argued were obvious or already in the public domain.

The case dragged on for three years, ultimately costing MakerBot an estimated $40 million in legal fees and settlement costs. Even though MakerBot had developed their technology independently, they couldn't prove they hadn't infringed on Stratasys' broad patents covering heated build platforms and automated support material removal.

The financial strain from this litigation significantly impacted MakerBot's ability to compete and innovate. The company was forced to redesign core components of their printers and delay several product launches while the legal battle continued.

Before beginning any 3D printing project, conduct thorough patent searches using professional databases like Google Patents, USPTO.gov, and specialized IP search tools. Focus on patents filed within the last 20 years, as older patents may have expired.

Pay particular attention to continuation and divisional patents, which can extend protection timelines beyond the original filing dates. When in doubt, consult with a patent attorney who can provide professional search services and freedom-to-operate analysis.

Document your search process and findings. This due diligence can help demonstrate good faith efforts to avoid infringement and may reduce potential damages in case of future disputes.

Copyright law protects the artistic and creative expression in original works, including 3D design files, sculptures, and decorative elements. While copyright doesn't protect purely functional designs, the line between functional and artistic expression often blurs in consumer products and decorative items.

Digital design files themselves receive copyright protection as computer code or digital artwork. Downloading, modifying, or redistributing these files without permission can constitute copyright infringement, even if the physical printed objects would be legally permissible to create.

The advent of online marketplaces for 3D design files has complicated copyright enforcement. Platforms like Thingiverse, MyMiniFactory, and Cults3D host millions of user-generated designs, not all of which respect existing copyright protections.

Disney has become notorious for aggressively protecting its copyrighted characters and designs from unauthorized 3D printing. The company employs sophisticated monitoring software to scan online marketplaces and social media platforms for infringing designs.

In 2019, Disney filed suit against several Etsy sellers offering 3D printed Mickey Mouse ears and Star Wars props. The sellers argued their designs were "inspired by" rather than copied from Disney properties, but the court found clear copyright infringement in the recognizable character elements.

The defendants faced damages ranging from $750 to $150,000 per infringed work, plus Disney's attorney fees. Several sellers were forced into bankruptcy, while others agreed to cease-and-desist orders that effectively shut down their businesses.

Disney's enforcement extends beyond obvious character reproductions to include architectural elements from theme parks, decorative patterns from animated films, and even general "Disney-style" aesthetic elements that too closely mimic the company's distinctive artistic expression.

Many businesses mistakenly believe that 3D printing copyrighted designs for "educational purposes" or "personal use" falls under fair use protection. However, commercial 3D printing operations rarely qualify for fair use defenses, even when the end use appears educational or transformative.

Fair use analysis considers four factors: purpose and character of use, nature of the copyrighted work, amount used, and effect on the market. Commercial 3D printing typically fails this test because it involves commercial use of substantial portions of protected works with potential market impact.

Trademark law protects brand identifiers like logos, company names, and distinctive product designs that consumers associate with specific sources of goods or services. 3D printing trademark violations typically involve unauthorized reproduction of branded logos or distinctive product shapes.

The key legal test for trademark infringement is likelihood of consumer confusion. If consumers might reasonably believe that a 3D printed product comes from or is endorsed by the trademark owner, infringement has likely occurred.

Even when selling obviously counterfeit goods, businesses can face severe penalties. Trademark counterfeiting carries statutory damages of up to $2 million per trademark per type of goods, plus seizure and destruction of infringing products.

Nike has pursued numerous trademark infringement cases against businesses offering custom 3D printed shoe components featuring the distinctive "Swoosh" logo. In a notable 2020 case, Nike sued a small business creating custom sneaker accessories with modified Swoosh designs.

The defendant argued that their modified logos were clearly different from Nike's trademark and that customers understood they were purchasing unauthorized custom products. However, Nike successfully demonstrated that the modified logos retained sufficient similarity to cause consumer confusion.

The case settled for an undisclosed amount, but court documents revealed Nike sought over $2 million in damages plus destruction of all infringing inventory. The small business was forced to rebrand completely and destroy thousands of dollars worth of finished products and design files.

Nike's enforcement strategy includes monitoring social media platforms, online marketplaces, and 3D printing communities for unauthorized use of their trademarks. The company has successfully obtained takedown orders against hundreds of 3D design files featuring Swoosh-like elements.

Develop distinctive design elements that don't reference existing trademarks or trade dress. Focus on creating unique aesthetic elements that can eventually become your own protectable intellectual property.

When drawing inspiration from existing products, analyze the specific elements that make those products recognizable to consumers. Avoid reproducing distinctive shapes, color combinations, or design patterns that consumers associate with particular brands.

Consider registering your own trademarks for distinctive design elements you create. This proactive approach provides legal protection for your original innovations and creates defensive value against future IP disputes.

Trade secrets protect confidential business information that derives economic value from being secret. In 3D printing contexts, trade secrets often involve proprietary manufacturing processes, unique material formulations, or internal component designs not visible in finished products.

3D scanning technology enables detailed reverse engineering of existing products, potentially exposing trade secrets embedded in physical designs. However, reverse engineering becomes legally problematic when it involves circumventing security measures or violating confidentiality agreements.

The legal line is often drawn based on how the information was obtained. Publicly available products can generally be reverse engineered, but accessing internal components or proprietary manufacturing data through deceptive means can constitute trade secret theft.

TechFlow Industries, a 3D printing service bureau, faced a $12 million trade secret lawsuit after reverse engineering proprietary automotive brake components for a client. The case began when Ford Motor Company discovered aftermarket brake parts that perfectly replicated internal cooling channel designs that had never been publicly disclosed.

Investigation revealed that TechFlow had obtained original Ford brake calipers through a third-party supplier and used advanced 3D scanning to create exact digital replicas. The scanning process revealed Ford's proprietary internal geometry, which had been developed through years of computational fluid dynamics research.

Ford successfully argued that the internal cooling channels constituted trade secrets because they weren't visible in assembled vehicles and provided significant performance advantages. The court found that TechFlow's scanning process was equivalent to industrial espionage, as it accessed confidential design information through unauthorized means.

The settlement required TechFlow to pay $12 million in damages, destroy all related design files, and implement comprehensive trade secret protection protocols. The case established important precedent about the limits of reverse engineering in 3D printing applications.

Successful IP compliance requires systematic policies and procedures that address all phases of the 3D printing workflow. Begin by establishing clear protocols for evaluating new projects, conducting IP searches, and documenting design processes.

Create standardized intake procedures for new 3D printing projects that include mandatory IP risk assessments. These assessments should identify potential patent, copyright, trademark, and trade secret issues before production begins.

Implement design review processes that involve both technical and legal evaluation of proposed products. This multi-disciplinary approach helps identify IP risks that might be missed by purely technical or legal analysis alone.

Establish clear policies governing the use of online design files, customer-provided designs, and third-party intellectual property. These policies should specify required permissions, licensing requirements, and prohibited activities.

Maintain detailed documentation of your design and development processes, including inspiration sources, design iterations, and decision rationales. This documentation can provide crucial evidence in case of IP disputes.

Implement version control systems for all design files that track changes, contributors, and approval processes. This systematic approach helps demonstrate independent development and can support non-infringement arguments.

Train all employees involved in 3D printing operations on IP compliance requirements and recognition of potential infringement issues. Regular training updates help maintain awareness as IP law and technology continue evolving.

Consult with intellectual property attorneys when dealing with complex products, valuable markets, or uncertain legal questions. Professional IP counsel can provide freedom-to-operate analyses, licensing guidance, and strategic advice tailored to your specific situation.

Consider professional consultation for any project involving medical devices, automotive components, or consumer electronics, as these industries have particularly complex IP landscapes with high enforcement activity.

Engage IP professionals early in the design process rather than after potential problems arise. Preventive legal consultation is almost always more cost-effective than reactive litigation defense.

Medical device 3D printing faces particularly stringent IP and regulatory requirements due to patient safety concerns and extensive patent coverage in the healthcare industry. The FDA's growing acceptance of 3D printed medical devices has increased both opportunities and IP risks.

Many fundamental 3D printing processes for medical applications are heavily patented, including specific printing methods for biocompatible materials, sterilization processes, and patient-specific customization techniques. Device manufacturers must navigate both traditional medical device patents and newer additive manufacturing patents.

Regulatory compliance adds another layer of complexity, as medical device approvals often require disclosure of manufacturing processes that could impact trade secret protections. Consider how regulatory requirements interact with IP strategies when developing medical 3D printing operations.

Consumer products and toys present unique IP challenges due to extensive design patent coverage, character licensing requirements, and safety regulations. Many common product shapes and decorative elements are protected by design patents that can be difficult to identify through traditional patent searches.

Toy manufacturing faces additional copyright and trademark risks from entertainment properties. Children's products often incorporate licensed characters, brand elements, or distinctive designs that require careful IP analysis and potential licensing agreements.

Safety regulations like CPSIA (Consumer Product Safety Improvement Act) requirements can impact IP strategies by requiring specific material compositions or manufacturing processes that might conflict with patent restrictions or trade secret protections.

Automotive and aerospace 3D printing operates in industries with extensive patent portfolios and strict safety requirements. Component manufacturers must consider both functional patents covering mechanical designs and process patents covering specific manufacturing methods.

Supply chain considerations become critical when 3D printing replacement parts or custom components for existing vehicles or aircraft. Original equipment manufacturers (OEMs) often have exclusive rights to certain component designs or access to proprietary specifications.

Certification requirements for safety-critical components may conflict with IP protection strategies. Parts used in flight-critical or safety-critical applications typically require extensive documentation and testing that could expose proprietary design elements.

Start by conducting a comprehensive audit of your current 3D printing operations to identify existing IP risks and compliance gaps. Review all current projects, design files, supplier relationships, and customer agreements for potential IP issues.

Develop written policies covering IP compliance in 3D printing operations, including procedures for new project evaluation, design file management, and employee training requirements. These policies should address both internal development projects and customer-provided designs.

Establish relationships with qualified IP professionals who understand 3D printing technology and can provide ongoing guidance as your operations evolve. Consider retaining both patent attorneys and copyright specialists depending on your product focus areas.

Implement systematic procedures for documenting design processes, conducting IP searches, and maintaining design file version control. These operational procedures provide the foundation for effective IP compliance and can be crucial in case of future disputes.

Create incident response procedures for handling IP infringement claims or identifying potential violations by others. Having predetermined response procedures helps minimize damage and ensures appropriate professional consultation when needed.

TechFlow Industries transformed their IP compliance approach after their costly automotive parts dispute by implementing a comprehensive protection framework. The company invested $200,000 in developing systematic IP policies and training programs that now guide all 3D printing operations.

Their new framework begins with mandatory IP risk assessments for every project over $10,000 in value. These assessments include professional patent searches, copyright analysis, and trademark clearance conducted by qualified IP attorneys before production authorization.

TechFlow implemented advanced design file management systems that track all source materials, design iterations, and approval processes. The system automatically flags potential IP risks and requires legal review before proceeding with flagged projects.

The company established partnerships with specialized IP firms in key markets and maintains ongoing legal counsel relationships that provide rapid response capabilities for urgent IP questions. This investment in professional relationships has prevented several potential disputes and saved an estimated $500,000 in avoided litigation costs.

TechFlow's comprehensive approach has become a competitive advantage, as customers increasingly value working with service providers who demonstrate serious IP compliance capabilities. The company has won several major contracts specifically because of their documented IP protection procedures.

The explosive growth of 3D printing technology creates unprecedented opportunities for innovative businesses, but it also exposes companies to significant intellectual property risks that can destroy unprepared operations. From patent infringement claims reaching tens of millions of dollars to copyright violations that force complete business shutdowns, IP disasters have become an unfortunate reality in the 3D printing industry.

The key to avoiding these costly mistakes lies in implementing comprehensive IP compliance strategies before problems arise. Successful 3D printing businesses invest in professional IP guidance, maintain systematic design documentation, and create clear policies governing the use of third-party intellectual property.

Don't wait until you receive a cease-and-desist letter to address IP compliance in your 3D printing operations. The cost of preventive measures pales in comparison to the potential damages from IP infringement litigation. Whether you're launching a new 3D printing venture or expanding existing operations, professional IP guidance and comprehensive compliance policies are essential investments in your business's future.

Legal GPS provides specialized contract templates and professional guidance specifically designed for 3D printing businesses navigating complex IP landscapes. Our Pro subscription includes access to IP compliance checklists, design review templates, and expert legal guidance to help protect your innovations while avoiding costly infringement disputes.

Legal GPS Pro

Protect your business with our complete legal subscription service, designed by top startup attorneys.

|

Premium Template

Single-use Template |

Legal GPS Pro

Unlimited Access, Best Value |

|

|

| Choose Template | Learn More |

| Trusted by 1000+ businesses | |

Table of Contents

Launching a mobile app feels like printing money until legal disasters strike. Most entrepreneurs dive into development thinking their biggest risk...

American companies spend over $366 billion annually on employee training programs, yet most business owners struggle to demonstrate meaningful return...

Home renovation should be exciting, not a legal nightmare. Yet statistics reveal a sobering truth: approximately 30% of major home renovation...